Manual probe stations, commonly known as manual probes, play a crucial role in testing electronic devices, especially for applications such as device characterization, wafer-level reliability, integrated circuit engineering, and failure analysis. In this article, we invite you to discover the specific features of manual probes and the advantages of the solutions offered by our partner, MPI Corporation.

What is a Manual Probe Testing Station?

A station de test sous pointes manuelle A manual probe test system is a device used to test semiconductors at the wafer level. It allows for the precise placement of test probes on circuit contact pads to perform electrical measurements. Manual probe test systems are essential for the development and debugging of electronic devices.

Manual probes have no motorization, which makes their use extremely flexible and gives them great robustness.

Given their manual operation, they are designed to perform a limited number of tests on a wafer (a few dozen at most), unlike an automated station designed to test one or more wafers partially or completely. However, testing a few individual chips for various applications and chip designs can be done accurately and efficiently on a manual station. The types of applications possible with a manual station are numerous: with micro-positionneurs (up to 12 at the same time), of cartes à pointes, for DC, RF, mmW, THz, Load-Pull, High Power (high current and high voltage), Silicon Photonics (SiPH), laser trimming measurements…

Finally, manual probe testing stations offer perfectly optimized operating costs. They have a low purchase cost, require little corrective maintenance, very limited preventive maintenance, and have low fluid and electricity consumption.

But be aware, a manual test station doesn’t mean a low-end, inaccurate, and unsafe test station: MPI manual test stations are designed for the most demanding applications and incorporate advanced features to provide flexibility, ergonomics, repeatability, precision, stability, and safety for users. Here are a few points that will convince you.

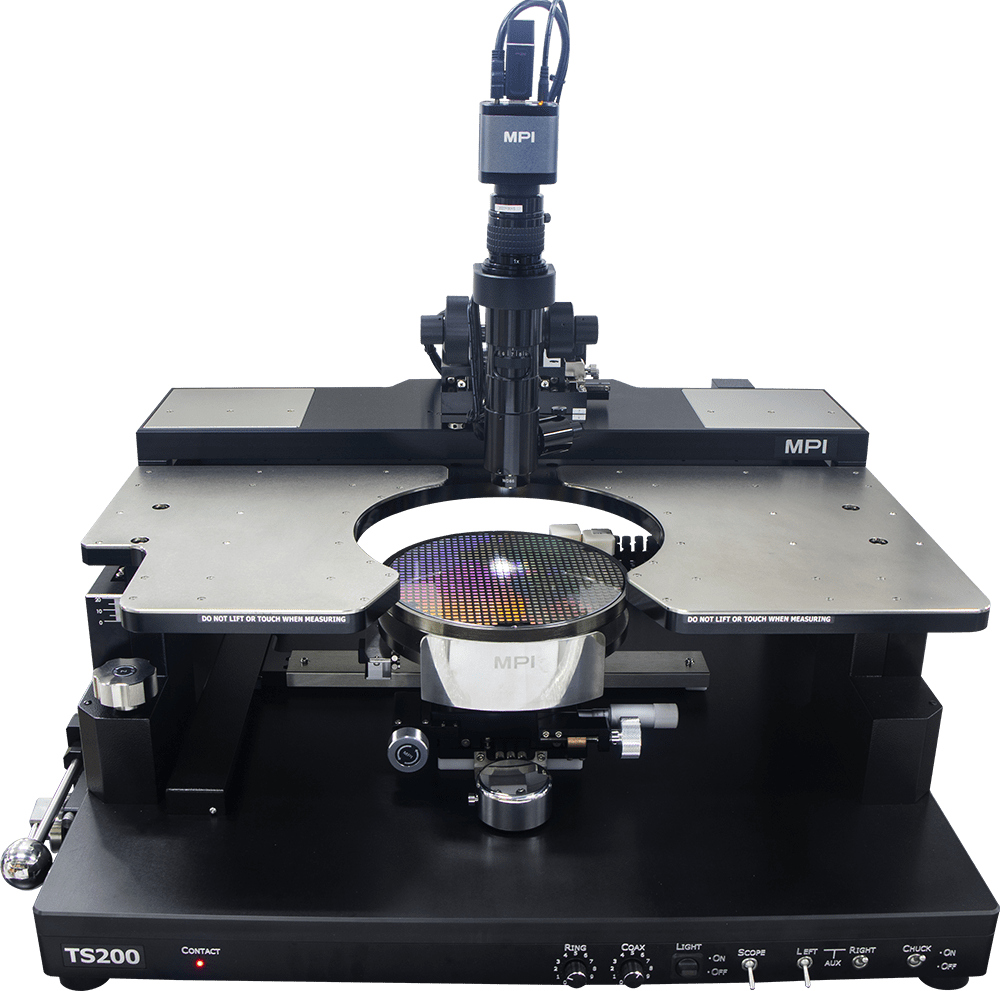

The TS150, TS200 and TS300 Systems from MPI Corporation

Flexibility and Ergonomics

The systèmes TS50, TS150, TS200 et TS300 MPIs are designed to accommodate wafers from 50 mm to 300 mm, across a wide variety of applications, such as:

- The characterization of the devices

- High-frequency (HF) modeling

- Brake pad reliability (WLR)

- Integrated circuit (IC) engineering

- MEMS and high-power testing

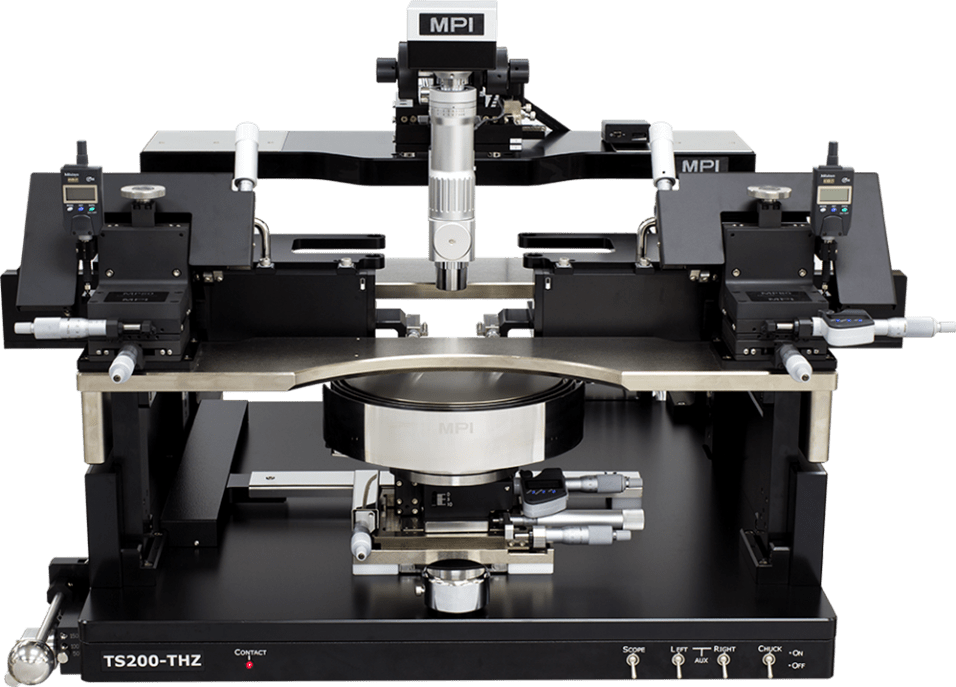

MPI stations are distinguished by their ergonomic design, in particular a plate movement with one-hand control, thus facilitating the quick and precise positioning of test tips.

Features of MPI Systems

MPI probe testing systems offer many advantageous features:

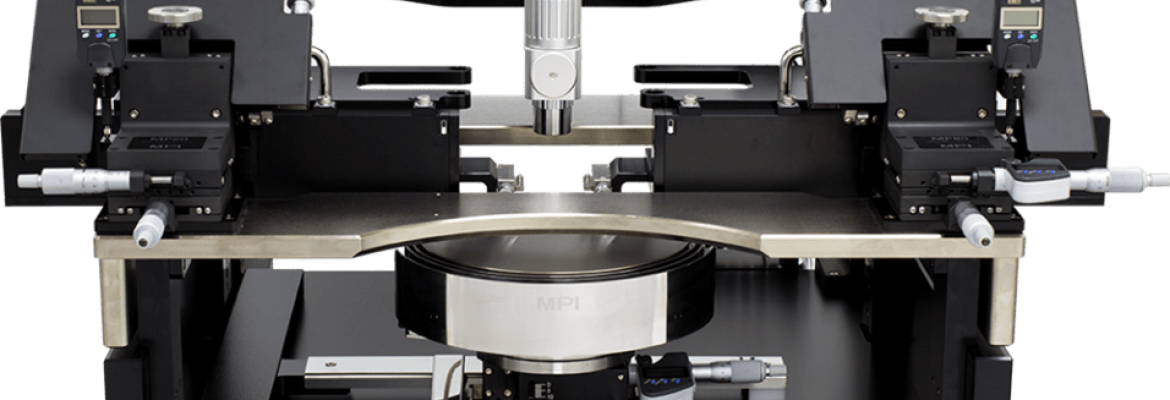

- Chuck motion using an air-cushioned puck: A smooth and maintenance-free motion allowing simple and quick movement with one hand.

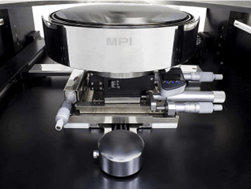

- Fine adjustment of the wafer position using precise micrometric screws and adjustment knobs for high placement accuracy.

- Fine adjustment of the turntable height: Up to 20 mm of adjustment to suit various applications, with an accuracy of 1 µm.

- Bridge for stable microscope: Provides a rigid and vibration-free platform, compatible with high-quality optical microscopes for a clear and precise view of the devices being tested.

- Unique vacuum controls: Easy access to vacuum controls from the front of the station, for different wafer areas and sizes.

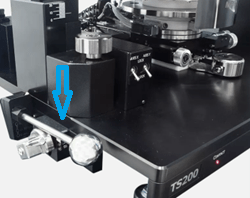

- The highly innovative assisted control/separation system features a MPI separation lever with three positions: a “separation” position 3 mm above contact, an “adjustment” position 300 µm above contact, and the “contact” position. The “adjustment” position allows for very precise adjustment of the tip position relative to the pads, and of both tips and pads within the focus area. Mechanical assistance slows the movement between the “adjustment” and “contact” positions to ensure repeatable tip placement and extended tip lifespan. This system is worthy of an automated workstation.

- The PHC (Probe Hover Control): this is an additional lever allowing the adjustment position to be set at 50, 100 or 150 µm above the contact to make the positioning of the tips even more precise.

- Contact safety: when the controller is in contact position, an LED alerts the user and the movement of the chuck via the puck is made impossible.

Targeted Applications

MPI test stations are also ideal for a variety of applications, including:

- The characterization of the devices

- High-power measurements

- RF & mmWave tests on a wafer

- IC engineering

- Brake pad reliability (WLR)

- Failure analysis

Options Disponibles

MPI also offers various options for adapting test stations to specific needs:

- Plates-formes d’isolation anti-vibrations

- Integrated test system tables

- EMI-shielded black boxes

- High-performance microscopes and cameras

- Micro-chamber for low-noise or negative-temperature DC measurements

- Dedicated platforms for mmW, THz or load-pull measurements

Why Choose a Prober Manual MPI?

The solutions offered by MPI Corporation for manual probe testing stations provide several key advantages:

Accuracy: MPI systems guarantee accurate measurements thanks to advanced motion technology and fine-tuning options.

Flexibility: Compatibility with a wide range of accessories and configurations to meet diverse needs.

Reliability : MPI stations are robust and designed to deliver stable and durable performance, even in demanding laboratory environments.

Ergonomics : The design is intended to facilitate use and reduce operator fatigue, allowing for more efficient and comfortable work.

A closer look at the TS150-THZ and TS200-THZ stations, dedicated to high-frequency applications

Mechanical Stability and Precision

The systems MPI TS150-THZ et le TS200-THZ, are designed to offer unparalleled stability. The large surface area stainless steel platform and the extremely stable turntable support reduce vibrations and ensure precise and reproducible contacts, essential for good calibrations and measurements in mmW and THz.

Integration of Frequency Extenders

MPI offers a unique integration of frequency extenders directly above the device under test (DUT), eliminating the need for additional waveguides above 220 GHz. This allows for excellent measurement dynamics and directivity, crucial for accurate testing at such high frequencies.

Precise Contact Maintenance

Thanks to advanced features such as over-travel control with 1 µm accuracy, and optional digital micrometers, MPI stations ensure stable and accurate positioning of test tips, even during complex initial setups.

Optical Zoom and Visibility

The systems utilize high-quality optical microscopes with magnification suitable for small pads, providing excellent visibility and efficient test setups for IC and RF devices. High-quality cameras also provide optimal viewing comfort.

The stations de test sous pointes manuelles are essential for testing and characterizing electronic circuits, including for complex applications in mmW and THz. The solutions offered by MPI Corporation provide unparalleled precision, flexibility of use and unwavering reliability, thus meeting the highest industry requirements.

To learn more about MPI products and view their datasheets, visit our site internet or on the MPI Corporation website.