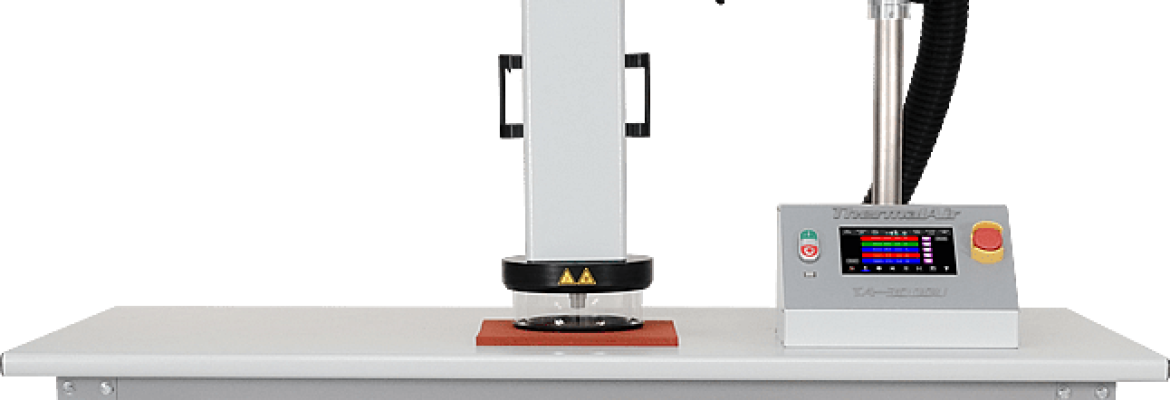

The TA-3000A and TA-3000B temperature conditioners: benchmarks for thermal testing

Giraffes TA-3000A et TA-3000B MPI Thermal products are essential solutions for the rapid and precise thermal control of electronic, optical and RF components or other DUTs (Device Under Test).

Key features and benefits:

- Extended temperature range: from -65 °C à +225 °C, ideal for reliability and characterization testing.

- Ultra Cold maintained at 50 Hz or 60 Hz for consistent performance.

- Interface tactile intuitive : contrôle des réglages, rampes et cycles directement au poste de test.

- Plug & Play : alimentation universelle 200 à 250 VAC sans reconfiguration lors des déplacements.

- Advanced Connectivity : USB for thermal file management and data logging.

- Controlled dry air purge : maintaining a frost-free test area during prolonged testing at very low temperatures.

- Multiple control modes : standard operator and programmed cycles (Temp Cycle, Ramp & Soak).

- Compatibility with existing systems:

- Central color touchscreen

- Interfaces IEEE-488.2 (GPIB), USB, Ethernet, Serial, LXI

- Connexion intranet via LAN

- LabVIEW drivers for integration into your test programs.

These Thermal Air models are highly praised for their flexibility, rapid thermal transition and compatibility with many accessories (glass bells, thermal chamber, nozzles, and custom accessories).

The TA-3000U It was designed to address a major challenge in today’s testing environments: space optimization. With production and laboratory spaces becoming increasingly expensive, every square centimeter counts.

Offering the same performance as the historical TA-3000A and B models (see above), this new giraffe (“ThermoStream”) completes the range to meet the most demanding environments in terms of floor space and on test benches.

This is why the TA-3000U adopts a modular and space-saving architecture, designed to fit under the test bench or away on the production floor, thus freeing up critical areas around workstations.

The “U” stands for Under-the-Bench, reflecting its streamlined design which fits discreetly under test benches, while maintaining the thermal performance of the TA-3000 series. This configuration is ideal for thermal testing (hot and cold), characterization or functional testing at temperature, while freeing up valuable space without compromising performance.

But the modularity of TA-3000U does not stop at its format:

- Detachable graphical interface: the control module (GUI) is completely independent and can be positioned wherever the engineer wants — on the bench, rack-mounted or integrated into the station for ergonomic access.

- Total adaptability: whether in R&D or production, the TA-3000U integrates easily into compact configurations without impacting available space.

- Localized precision: it ensures precise thermal control for hot and cold tests directly at the test station.

In a context where the cost of test areas, particularly in cleanrooms or production areas, is extremely high due to environmental constraints and the necessary infrastructure, the TA-3000U offers a modular and economical solution, allowing for efficient and customized installation, while optimizing available space.

The TA-3000U is perfectly suited to environments where compactness and performance are essential:

- R&D laboratories: easy integration under existing benches.

- Production: mobility thanks to its compact size and wheels.

Compact size of the TA-5000U, modular layout, ergonomic workstation, optimized workspace

An eco-responsible system

The TA-3000U operates without liquid nitrogen (LN₂) or CO₂, reducing environmental impact and operating costs.

- Optimized consumption: up to 50% energy savings compared to traditional systems.

- Clean technology: no frost, no greenhouse gases, simplified maintenance.

- An air drying module is available to prevent condensation.

Contact Microtest to learn more

Microtest, official distributor of MPI Thermal solutions, assists you in choosing and integrating the TA-3000U.

📧 Email : microtest@microtest-semi.com

📞 Téléphone : +33 (0)4 90 40 60 90

🌐 Site web : www.microtest-semi.com