Microtest is proud to work with MPI Corporation, a leading manufacturer of temperature test equipment and probers for the semiconductor industry. MPI Corporation supplies a wide range of test equipment, from manual to fully automated systems, enabling companies to meet the complex and demanding needs of industry, laboratories and R&D.

MPI Corporation is renowned for its manufacturing quality and commitment to innovation. The company has an ISO 9001-certified quality management system and is committed to research and development programs to continually improve its products and services. MPI Corporation probers also comply with environmental and safety standards, including RoHS and CE.

Founded in 1995, MPI Corporation is based in Hsinchu, Taiwan, where Nicolas and Laurent spent a week reinforcing our skills in the products and innovations of the Photonic Automation and Advanced Semiconductor Test divisions.

It’s vital for Microtest to take part in these events, so that we can continue to improve our skills in these 2 areas, and provide our customers with the best possible advice on the solutions developed by our partners.

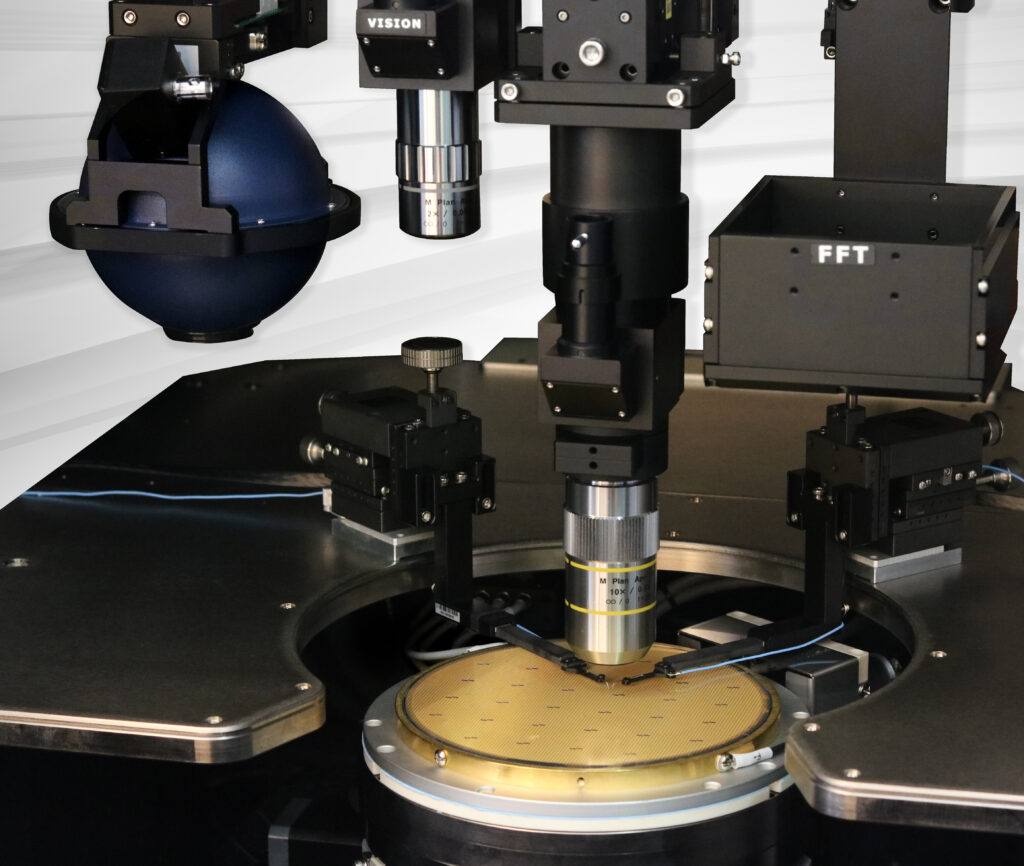

We started with products from the Photonic Automation division, which offers a wide range of innovative photonic and optoelectronic measurement solutions for production and R&D.

We were able to observe the different product ranges in detail thanks to several demonstration sessions:

- The VEGA range: photonic probing and measurement equipment for VCSEL, EEL and PD applications in the field of optical detection;

- The AVIOR range: photonic probing and measurement equipment for VCSEL, EEL and PD applications in optical communications;

- The GEMINI range: wafer probing and photonics measurement equipment for micro-LEDs;

- The CAPELLA range: on-wafer photonics probing and measurement equipment for mini-LEDs and traditional LEDs;

- The TP Serie range of production probers: modular and compact for 200 mm wafers, allowing up to 4 probing stations to be positioned around an automatic loader in a highly optimized space;

- The ST Serie sorter range: efficient and super-fast with up to 4 sorter arms for increased productivity;

- The AVI Serie range: modular inspection systems with automatic loader, incorporating advanced features such as artificial intelligence.

We continued with the products of the Advanced Semiconductor Test division, with its rich range of R&D and production probers for many types of application. Once again, a great deal of time was devoted to demonstrating the products, so as to fully understand the key points of each application.

Numerous innovations were on show:

- New features for the SENTIO operating software, which is making daily progress in user ergonomics;

- The performance of QAlibria software, free for all, the only RF calibration software integrating the best algorithms for calibration of up to 4 RF ports, with ease of use;

- The unique RF/mmW test configuration up to 220 GHz perfectly integrated into MPI test stations with THz selection;

- The productivity of test stations incorporating the WaferWallet automatic loader and the unique sequencer developed with Celadon for automatic loading of up to 5 different tip cards;

- MPI’s solutions for silicon photonics (SiPH) measurements feature the best alignment performance on the market for fully automated measurements;

- The new range of manual prober for RF measurement on PCBs: incredibly flexible.

Our warmest thanks to MPI Corporation for these 5 exciting and rewarding days! A pragmatic approach focused on customer satisfaction.

And let’s not forget the convivial moments we shared outside the technical training courses, which forged human links to ensure that our MPI-Microtest team is ever more efficient and responsive to customer needs.

Thanks to our extensive expertise in Photonic Automation and Advanced Semiconductor Test, we can offer you reliable, adaptable, high-quality solutions to meet your testing needs, with a high degree of ergonomics.